Choosing a 12V to 48V DC-DC step-up converter isn’t just about picking something that looks good on paper. Different applications demand different things—whether it’s current capacity, voltage stability, efficiency, or protection features. Get it wrong, and you could end up with damaged equipment or an unstable system.

Let’s break down, step-by-step, what you should really be looking for.

1. Know Your Input and Output Requirements

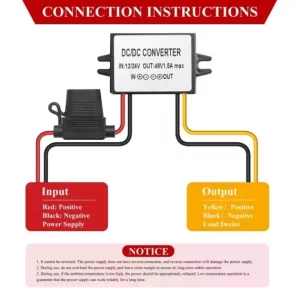

Before anything else, make sure you’re clear about your input and output needs. Even though the converter is labeled “12V input,” in real-world use, that input voltage often fluctuates. It might drop to 11V or surge up to 14V, depending on your power source (like a battery, solar panel, or vehicle system). A good converter should handle these variations without breaking a sweat.

Same thing with output: are you looking for a rock-solid 48V, or is a little variation acceptable? Sensitive electronics will need very stable output, while some motors or LED systems might tolerate small swings.

Pro Tip: Always check the input voltage range and the output voltage regulation in the datasheet—not just the big numbers on the product page.

2. Calculate How Much Power You Really Need

It’s easy to underestimate how much current your system will draw at 48V. Remember, power (W) = voltage (V) × current (A).

If your load needs, say, 5A at 48V, that’s 240W. And because of energy conversion inefficiencies, your input side will draw even more than that. A rough estimate: if the converter is 90% efficient, your 12V input would need around 22A to deliver 240W out.

That’s a lot! Make sure your power supply can handle it, and that the converter is rated for both the input and output sides. Oversizing the converter a little is smart—you don’t want it running at 100% load all the time.

3. Check the Efficiency

Higher efficiency isn’t just a “nice to have.” A converter that’s only 80% efficient will get hotter and waste a ton of energy, especially under heavy loads. Heat leads to shorter lifespan and reliability issues.

Look for converters with efficiency ratings above 90%, especially if you’re running anything continuous or mission-critical.

And if the datasheet shows an efficiency curve, even better—you’ll want to check how the efficiency holds up across different loads, not just at the “ideal” rated point.

4. Pay Attention to Protections

A good step-up converter should have basic protections built-in:

- Overcurrent Protection (OCP): Shuts down or limits the output if the load tries to pull too much current.

- Overvoltage Protection (OVP): Stops dangerous voltage spikes from damaging your load.

- Overtemperature Protection (OTP): Prevents the converter from frying itself if it gets too hot.

- Short-circuit Protection: Essential, especially if you’re powering sensitive or expensive equipment.

Don’t skip these. Even if you think “that’ll never happen,” real-world setups often surprise you.

5. Think About Cooling

Converters under heavy load can get seriously hot. Some models rely purely on natural air cooling (passive cooling), while others have fans (active cooling).

- Passive cooling is silent and reliable but needs good airflow around the converter.

- Active cooling (fans) helps manage higher power but can fail over time and introduce noise.

If your system will be in a tight, poorly ventilated space, you either need a converter with exceptional passive cooling—or you’ll have to plan for external fans or heat sinks.

6. Size and Mounting

Depending on your project, physical size might matter more than you think. Some DC-DC converters are compact and easy to mount; others are heavy and bulky.

Check dimensions, weight, and mounting options (like screw holes, DIN rail clips, or adhesive pads). Make sure the form factor fits your setup and that it’s secure enough to handle vibrations if it’s going into a vehicle or outdoor environment.

7. Certifications and Build Quality

If you’re working on anything commercial, or where safety is critical, check if the converter is certified (CE, UL, RoHS, etc.). Certified products usually meet stricter quality and safety standards.

And don’t underestimate build quality. A $10 no-name converter might work fine on your bench, but in the field under real load and stress, it could fail fast. Look for quality connectors, good soldering, and solid casings.

Choosing the right 12V to 48V DC-DC converter is about understanding your needs, doing a little math, and paying close attention to the details. Power demands, voltage stability, efficiency, protection features—each one plays a big role in whether your system will be reliable or a headache.

Take the time to get it right upfront, and you’ll save yourself a ton of problems down the road.