DC to DC Converter 24V to 12V: Working Principle and Key Technologies

Why 24V to 12V DC Conversion Matters

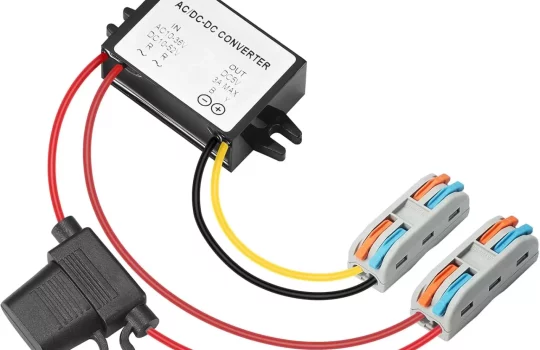

DC-DC converters play a crucial role in modern power systems, enabling efficient voltage step-down to match different loads. The 24V to 12V DC-DC converter is widely used in automotive systems, industrial control circuits, telecommunications, and renewable energy applications. These converters ensure that sensitive electronic components receive the right voltage while optimizing power efficiency and reducing heat generation.

This article explores the working principle, core technologies, and advanced techniques that enhance the performance and efficiency of 24V to 12V DC-DC converters.

1、Understanding the Working Principle

A DC-DC converter is an electronic circuit that steps down the voltage level from 24V to 12V while maintaining high efficiency. The most commonly used topology for this conversion is the buck converter, also known as a step-down converter.

1.1 Basic Operation of a Buck Converter

The buck converter consists of four key components:

- Switching Element (MOSFET or IGBT): Controls the on/off state of the circuit to regulate energy flow.

- Inductor: Stores and releases energy, ensuring smooth voltage transformation.

- Diode (or Synchronous Rectifier): Provides a freewheeling path for current when the switch is off.

- Capacitor: Filters output voltage, reducing ripple and ensuring a steady 12V output.

1.2 Step-by-Step Working Process

- Switch ON Phase:

- The MOSFET turns on, allowing current to flow from the 24V input through the inductor to the load.

- The inductor stores energy in its magnetic field.

- Switch OFF Phase:

- The MOSFET turns off, disconnecting the direct 24V source.

- The stored energy in the inductor maintains current flow, delivering power to the load via the diode or synchronous rectifier.

- Voltage Regulation:

- A feedback control circuit adjusts the duty cycle (the percentage of time the MOSFET is ON) to maintain a steady 12V output despite load variations.

By rapidly switching on and off, this process efficiently steps down 24V to 12V while minimizing power loss.

2、Key Technologies in 24V to 12V DC-DC Converters

To achieve high efficiency, reliability, and compact design, several advanced technologies are used in modern DC-DC converters.

2.1 Synchronous Rectification

Instead of using a Schottky diode (which has a voltage drop of around 0.3V-0.5V), modern designs replace it with a MOSFET operating as a synchronous rectifier. This reduces conduction losses and improves efficiency, especially in high-current applications.

2.2 High-Frequency Switching

Increasing the switching frequency allows for smaller inductors and capacitors, reducing overall converter size. However, high-frequency operation also increases switching losses, so advanced techniques like soft-switching (ZVS/ZCS) are used to reduce energy dissipation.

2.3 Pulse Width Modulation (PWM) Control

A PWM controller dynamically adjusts the duty cycle of the switching MOSFET to regulate voltage output. Advanced digital PWM controllers optimize efficiency across varying load conditions.

2.4 Multi-Phase Interleaving

For high-power applications, interleaved buck converters use multiple parallel converter stages operating out-of-phase. This reduces current ripple, improves thermal performance, and enhances efficiency.

2.5 Thermal Management

Heat dissipation is a major concern in DC-DC converters. Technologies such as:

- Copper PCB layouts with thermal vias

- Integrated heat sinks

- Efficient cooling mechanisms help maintain reliable performance under heavy loads

3、Efficiency Optimization Strategies

Reducing power loss is crucial for improving the efficiency of 24V to 12V converters. Key optimization techniques include:

3.1 Selecting Low Rds(on) MOSFETs

MOSFETs with lower on-state resistance (Rds(on)) minimize conduction losses, improving overall efficiency.

3.2 Using Low-Core-Loss Inductors

Ferrite-core inductors with minimal hysteresis and eddy current losses contribute to higher efficiency and lower thermal buildup.

3.3 Implementing Adaptive Control Algorithms

Modern converters use adaptive voltage positioning (AVP) and dynamic load response control to fine-tune efficiency under varying loads.

3.4 Reducing Parasitic Losses

Optimized PCB layout techniques help minimize parasitic capacitance and inductance, reducing unwanted power dissipation and improving stability.

4、Applications of 24V to 12V DC-DC Converters

These converters are widely used across multiple industries due to their high efficiency, reliability, and adaptability.

4.1 Automotive Electronics

- Powers infotainment systems, sensors, and microcontrollers from a 24V truck or bus battery.

- Used in electric vehicle (EV) power management systems.

4.2 Industrial Control Systems

- Provides stable 12V output for PLC controllers, sensors, and automation devices.

- Used in robotics and factory automation.

4.3 Telecommunications Equipment

- Regulates power in network infrastructure, routers, and wireless communication systems.

4.4 Renewable Energy Systems

- Converts solar panel or wind turbine output to stable 12V for battery charging and off-grid applications.

The Future of 24V to 12V DC-DC Conversion

The demand for efficient, compact, and reliable 24V to 12V DC-DC converters continues to grow. Innovations such as wide-bandgap semiconductors (GaN, SiC), AI-driven power management, and ultra-high-frequency designs will further enhance efficiency and reduce size.

By leveraging advanced topologies, control techniques, and component selection, modern DC-DC converters can achieve efficiency levels above 90%, ensuring optimal power utilization across various applications.

With continuous advancements in power electronics and energy management, the future of DC-DC conversion is set to revolutionize industries, making power supplies more compact, efficient, and intelligent than ever before.